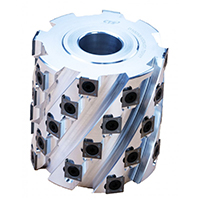

The JET 12" jointer-planer JPT-310 with 56 carbide knives spiral cutterhead is now being retrofitted by woodworkers onto their old planers and jointers due to the numerous benefits it provides:

A smoother finish with no tear-out due to each knife sitting at a slight angle, resulting in a shear cut. The staggered cut of the spiral cutterhead produces a much better surface finish than a single straight cut, eliminating tear-out and leaving a glossy surface on even highly figured hardwood.

Reduced noise levels as the spiral cutterhead allows a few knives to cut in a staggered pattern.

A lifespan more than 10 times longer than high-speed steel due to the use of 15x15x2.5mm inserts made of sintered tungsten carbide, which is much harder than high-speed steel. Each insert has four edges.

Easy replacement of knives as they are interchangeable and precision-ground to a tolerance of +/-0.0004" or +/-0.01mm. In just minutes, loosen the screw, rotate the knife 90° for a new edge, and tighten the insert.

Easier dust extraction due to the thinner and shorter chips produced by the spiral cutterhead.

A cost-effective solution as the spiral cutterhead produces a smooth finish, reduces or eliminates the need for sanding, and does not require sharpening. The product pays for itself in a short period of time.

Differences before and after Sheartak spiral cutterhead is installed.

Ask Question About Product

| Technical | |

| Material of Cutterblock | Alloy Steel |

| No. of Spirals | 4 |

| No. of Carbide Inserts | 56 |

| Carbide Insert Size | 15x15x2.5mm R150 30° |

| Standard Kit | |

| No. of Additional Knives | 5 |

| No. of Additional Screws | 5 |

| No. of Wrenches | 1 |