Frequently Asked Questions

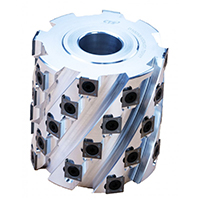

The carbide knives on our cutter blocks are arranged either at a slight angle or parallel to the centerline of the block, creating two types of cutterheads: spiral and helical.

The carbide knives on spiral cutterheads are angled, creating a shear cut action when they approach the board. Only a short section of the edges cut at a time, resulting in a high-quality finish. In contrast, helical cutterheads have straight-edged carbide knives that cut straight across the board. It's widely accepted that a shear cut is superior to a straight cut.

Below is the comparison.

Descriptions |

Spiral Cutterhead |

Helical Cutterhead |

Cutter Edge |

Round (Ours is R150) |

Straight |

Angle to Centerline |

10° to 15° |

Zero |

Cut type |

Shear |

Straight |

Chips |

Thinner and Shorter |

Good |

Surface Finish |

Better |

Good |

Dust Extraction |

Better |

Good |

Our heavy-duty helical cutterheads feature two-edge carbide inserts that measure 30x12x1.5mm. The inserts are securely held in place with wedges, allowing for heavy cutting of up to 8 to 10mm in a single pass. Our cutterheads also feature a unique design where all carbide inserts are placed at a slight angle to the feeding direction, resulting in a shear-cutting action. In addition, all four corners are slightly chamfered, which helps to produce a smooth surface finish.

If the bearings in your machine are in good condition, they can be reused by removing them carefully with a bearing or pulley puller. However, if the bearings are tightly pressed onto the shaft, removing them can cause damage. To avoid this risk, we recommend replacing old bearings with our greased and sealed bearings, which are designed for lifelong use. We suggest adding the bearings to your shopping cart before checkout to ensure a successful upgrade.

Our spiral cutterheads are dynamically balanced to meet industrial-grade standards and can operate at the maximum speed allowed by your planer or jointer. Additionally, the dynamic balancing process is completed with all carbide inserts pre-installed, ensuring optimal performance and precision.

Our inserts are designed with an angled shear-cut, and the screws are positioned in taper holes to ensure secure locking. When tightening the screws, it's important to keep the wrench square to the screw head face to achieve the best results.

Old-style cutterhead features a long, straight blade that hammers wood in its full length at once, creating an annoyingly loud noise that may cause complaints from your loved ones and neighbors, or require them to endure the sound. However, with our Sheartak spiral cutterheads, only a few carbide inserts cut at continuous intervals, resulting in weaker sounds. Our customers report that installing our spiral cutterheads can reduce noise levels by 15 to 20 decibels. This is just one of the many significant improvements our cutterheads offer.

Are more knives on the spiral cutterhead worth the extra $$$? It depends.

When comparing the prices of spiral cutterheads from different suppliers, it's essential to consider the quantities of carbide knives on the cutterheads, rather than solely focusing on the number of spirals or helical grooves. It's important to understand that tools function differently than humans, and each knife on the spiral cutterhead is equally efficient and productive as another. However, having more knives on the spirals can result in more value and productivity. The number of knives that are suitable for your needs will depend on how often you operate your jointer or planer and the scope of your project. For instance, we offer spiral cutterheads with 4, 5, 6, 8, 9, or 12 spirals for the same planer with a 120mm diameter cutterhead, and each spiral has the same quantity of carbide knives. Ultimately, the choice between dollars and performance will depend on your woodworking needs. If woodworking is just a hobby, a spiral cutterhead with knives that are sufficient will do the job. However, if you operate a mill and run machines for extended periods daily, more knives are the best bet for optimal performance. Please feel free to contact us for assistance in choosing the proper cutterhead for your needs.

According to feedback from our customers, our carbide inserts have an average lifespan that is 10 times longer than standard straight HSS blades when used for regular cutting. Additionally, the square inserts feature four indexable edges, and a single set of carbide inserts is equivalent in value to 40 to 50 fresh HSS blades.

Our carbide inserts are manufactured using tungsten Grade C3++ or K10. We offer carbide inserts with different grades and cutting angles to suit various applications and materials. If you have any questions or concerns regarding which carbide inserts would be best for your specific needs, please don't hesitate to contact us for assistance.

Thicknessers, jointers, and combination planers are designed for simplicity in operation and durability in construction. To achieve this, heavy-duty materials such as cast-iron and machined steel components are used along with powerful motors and heavy-duty bearings, especially in older machines that are still in good shape.

The straight knife cutter block has always been a challenge due to noise creation, frequent sharpening and maintenance requirements, and the need for skilled technicians to ensure accurate alignment. Even new machines suffer from this issue as straight blades become dull quickly.

Fortunately, spiral cutters with tungsten inserts solve these problems. They provide quality cut surface finishes, reduced noise, no sharpening, easy setup, long blade longevity, easy chip extraction, and a reduction in sanding required afterwards.

If you come across an old machine in good condition at a good price, don't hesitate to buy it. By installing a Sheartak spiral cutterhead, you can transform it into a better machine than a brand new one with long straight HSS blades.

What is the optimal number and configuration of inserts for a cutting head?

This is a common question because some machines on the market have fewer inserts. The main advantage of a Sheartak spiral cutterhead is its staggered shear-cut action, where each carbide insert cuts only part of its length at a time, resulting in a smoother finish. In contrast, most European cutterheads have straight-edge inserts that cut the whole length.

To determine the number of inserts needed, consider the spiral cutterhead fitting DW735, which has a standard configuration of 40 carbide inserts, resulting in a total cutting length of 600mm. In comparison, the straight blade length of the old-style cutterhead is 330mm. Therefore, 40 inserts take up 2/1.82=110% of the workload.

Other helical cutterheads may have fewer inserts, such as 30, resulting in a total effective cutting length of 1.365 straight blades. This design produces more noise, a less smooth finish, and places more pressure on the bearings.

The optimal number of inserts depends on how frequently the machine is used. For industrial use and heavy cutting, more spirals are recommended, while hobbyists can use four spirals. The DW735, our best-selling cutterhead with a cutting diameter of approximately 50mm, has 40 carbide inserts on four spirals. While it's possible to use 30 inserts instead, it will not produce the same result as the 40-insert version.

The cutter block is constructed using GB/T 40Cr, a structural alloy steel of the same caliber as ASTM grade 5140, AISI 5140, SAE 5140, DIN 41Cr4, BS 41Cr4, JIS SCr440, and EN 41Cr4.

The primary components of this steel are as follows: carbon (C) at a range of 0.37-0.44%, silicon (Si) between 0.17-0.37%, manganese (Mn) within 0.50-0.80%, and chromium (Cr) from 0.80-1.10%.

In terms of physical properties, this steel exhibits a tensile strength range of 115-234σb/MPa, a yield strength of 2σ 0.2 ≥/MPa, and an elongation capacity of 65 δ5≥ (%). It also has a HBS range of 123-321 and a HRC rating of 30.

This alloy steel is frequently utilized in low to moderately stressed components for machines, engines, and vehicles.

Achieving dynamic balance is crucial in minimizing vibrations while the helical cutterheads are in operation. Drilling holes is one way to accomplish this. At our company, all of our cutterheads are balanced to Grade G2.5 ISO1940 with the blades preinstalled. If any blade(s) happen to break off, they should be promptly replaced with new ones to maintain optimal performance.

The product price and shipping and handling cost do not include import duties, taxes, or brokerage fees. As the transportation fee for your order is the only fee we charge, it is the buyer's responsibility to pay for these charges. We recommend that you contact your country's customs office or visit their website to determine if there will be any additional costs.

The Harmonized Tariff Schedule (HS code) for spiral cutterheads and other woodworking tools is 8466.92.50.10.

Although installing carbide insert cutters is straightforward, it still requires careful attention to ensure it is done correctly. To do so, please download the manual linked below and follow the instructions presented in the manual and accompanying video:

Manual: https://www.sheartak.com/shearcut.pdf

Video: https://sheartak.com/video/spiralcutterhead.mp4

We've received a shared experience from Merle in New Mexico who installed carbide inserts for the Hitachi F1000A spiral cutterhead OEM version.

I went through the whole process for the third time very carefully to identify which two cutters were on either side of the high spot. I took those out and just to be sure I replace them with two different ones, clean those, clean the seat, and blew out the hole with compressed air. I tried planing again and I still had the problem but it seemed like it Moved over one cutter. So I did that same thing all over again with the two cutters in that position, and when I ran the board through again it came out perfect. I’m guessing it was not replacing the cutters that fixed it, but just the fact of taking them out and very carefully cleaning everything for the third time.

To lock the carbide inserts, we suggest using a torque of 48 to 52 Pound-Inch or 5.42 to 5.88 Newton-Meter. (1 Newton-Meter is equal to 8.851 Pound-Inch, or 1 Pound-Inch is equivalent to 0.112981584 Newton-Meter.) It is important to avoid using too much torque as this may cause the carbide inserts to explode. Using less torque will not adequately secure the inserts, which may lead to cracks, shattering, or ridges/lines on the board as the inserts cannot remain at the same height on the cutter block.

If your machine is maintained by a single person, they can typically apply the same torque without requiring a torque wrench. However, if multiple people are responsible for maintaining your machine, it can be challenging to ensure that the same torques are consistently applied when tightening the screws. For peace of mind, we recommend using a torque wrench.

The majority of our cutterheads are manufactured in sizes that are determined by machine owners who understand the advantages of helical or spiral cutting technology. Unfortunately, machine manufacturers are not always helpful in aiding their customers with retrofitting, making it challenging to obtain their assistance. Although we lack machines and have limited installation manuals or videos, we do provide instructional support.

Fortunately, there are numerous installation videos shared by passionate woodworkers and helpful tips shared on various forums. It can be enjoyable and highly rewarding to upgrade your machines.

To sign up for our website, simply enter your email address and create a password. Once you have submitted your information, please check your email for an activation letter. Click the button in the email to confirm your registration, then sign in to our website again. Complete your shipping information by providing your address and phone number. Once you're on the front page, collect your coupon, and search for products that you would like to purchase. Add the products to your shopping cart and make sure to apply the coupon before checking out.

Please note that promotional offers and coupons cannot be combined or applied to previous purchases.

Metric Tap and Drill Chart

| Tap Drill | Clearance Drill | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Aluminum, Brass, Plastics | Steel, Stainless Steel, Iron | Close Fit | Standard Fit | |||||||

| 75% Thread | 50% Thread | |||||||||

| Thread Size | Major Dia (mm) | Pitch (mm) | Drill Size | Closest Imperial | Drill Size(mm) |

Closest Imperial |

Drill Size | Closest Imperial | Drill Size | Closest Imperial |

| M1.5 x 0.35 | 1.5 | 0.35 | 1.15 | #56 | 1.60 | #55 | 1.6 | 1/16 | 1.65 | #52 |

| M1.6 x 0.35 | 1.6 | 0.35 | 1.25 | #55 | 1.70 | #54 | 1.8 | #49 | 1.75 | #50 |

| M1.8 x 0.35 | 1.8 | 0.35 | 1.45 | #53 | 1.90 | 1/16 | 1.9 | #49 | 2.00 | 5/64 |

| M2 x 0.45 | 2 | 0.45 | 1.55 | 1/16 | 1.70 | #51 | 2.1 | #45 | 2.20 | #44 |

| M2 x 0.4 | 2 | 0.40 | 1.6 | #52 | 1.75 | #50 | ||||

| M2.2 x 0.45 | 2.2 | 0.45 | 1.75 | #50 | 1.90 | #48 | 2.30 | 3/32 | 2.40 | #41 |

| M2.5 x 0.45 | 2.5 | 0.45 | 2.05 | #46 | 2.65 | #44 | 2.9 | #32 | 2.75 | 7/64 |

| M3 x 0.5 | 3 | 0.5 | 2.5 | #39 | 2.70 | #36 | 3.4 | #29 | 3.30 | #30 |

| M3.5 x 0.6 | 3.5 | 0.6 | 2.9 | #32 | 3.10 | #31 | 3.9 | #23 | 3.85 | #24 |

| M4 x 0.75 | 4 | 0.75 | 3.25 | #30 | 3.50 | #28 | 4.20 | #19 | 4.40 | #17 |

| M4 x 0.7 | 4 | 0.7 | 3.3 | #30 | 3.50 | #28 | ||||

| M4.5 x 0.75 | 4.5 | 0.75 | 3.75 | #25 | 4.00 | #22 | 4.75 | #13 | 5.00 | #9 |

| M5 x 1.00 | 5 | 1.0 | 4.00 | #21 | 4.40 | 11/64 | 5.25 | #5 | 5.50 | 7/32 |

| M5 x 0.9 | 5 | 0.9 | 4.10 | #20 | 4.40 | #17 | ||||

| M5 x 0.8 | 5 | 0.8 | 4.2 | #19 | 4.50 | #16 | ||||

| M5.5 x 0.90 | 5.5 | 0.9 | 4.60 | #14 | 4.90 | #10 | 5.80 | #1 | 6.10 | B |

| M6 x 1 | 6 | 1 | 5 | #8 | 5.40 | #4 | 6.30 | E | 6.60 | G |

| M6 x 0.75 | 6 | 0.75 | 5.25 | #4 | 5.50 | 7/32 | ||||

| M7 x 1.00 | 7 | 1.00 | 6.00 | B | 6.40 | E | 7.40 | L | 7.70 | N |

| M7 x 0.75 | 7 | 0.75 | 6.25 | D | 6.50 | F | ||||

| M8 x 1.25 | 8 | 1.25 | 6.8 | H | 7.20 | J | 8.40 | Q | 8.80 | S |

| M8 x 1 | 8 | 1 | 7 | J | 7.40 | L | ||||

| M9 x 1.25 | 9 | 1.25 | 7.80 | N | 8.20 | P | 9.50 | 3/8 | 9.90 | 25/64 |

| M9 x 1.0 | 9 | 1.0 | 8.00 | O | 8.40 | 21/64 | ||||

| M10 x 1.5 | 10 | 1.5 | 8.5 | R | 9.00 | T | 10.50 | Z | 11.00 | 7/16 |

| M10 x 1.25 | 10 | 1.25 | 8.8 | 11/32 | 9.20 | 23/64 | ||||

| M10 x 1.0 | 10 | 1.00 | 9.0 | T | 9.40 | U | ||||

| M11 x 1.50 | 11 | 1.50 | 9.50 | 3/8 | 10.00 | X | 11.60 | 29/64 | 12.10 | 15/32 |

| M12 x 1.75 | 12 | 1.75 | 10.2 | 13/32 | 10.90 | 27/64 | 12.60 | 1/2 | 13.20 | 33/64 |

| M12 x 1.50 | 12 | 1.50 | 10.50 | Z | 1.00 | 7/16 | ||||

| M12 x 1.25 | 12 | 1.25 | 10.8 | 27/64 | 11.20 | 7/16 | ||||

| M14 x 2 | 14 | 2 | 12 | 15/32 | 12.70 | 1/2 | 14.75 | 37/64 | 15.50 | 39/64 |

| M14 x 1.5 | 14 | 1.5 | 12.5 | 1/2 | 13.00 | 33/64 | ||||

| M14 x 1.25 | 14 | 1.25 | 12.8 | 1/2 | 13.2 | 33/64 | ||||

| M16 x 2 | 16 | 2 | 14 | 35/64 | 14.75 | 37/64 | 16.75 | 21/32 | 17.50 | 11/16 |

| M16 x 1.5 | 16 | 1.5 | 14.5 | 37/64 | 15.00 | 19/32 | ||||

| M18 x 2.5 | 18 | 2.5 | 15.5 | 39/64 | 16.50 | 41/64 | 19 | 3/4 | 20.00 | 25/32 |

| M18 x 2.0 | 18 | 2.0 | 16.00 | 5/8 | 16.75 | 21/32 | ||||

| M18 x 1.5 | 18 | 1.5 | 16.5 | 21/32 | 17.00 | 43/64 | ||||

| M20 x 2.5 | 20 | 2.5 | 17.5 | 11/16 | 18.50 | 23/32 | 21 | 53/64 | 22.00 | 55/64 |

| M20 x 2.00 | 20 | 2.0 | 18.00 | 45/64 | 18.50 | 46/64 | ||||

| M20 x 1.5 | 20 | 1.5 | 18.5 | 47/64 | 19.00 | 3/4 | ||||

| M22 x 2.5 | 22 | 2.5 | 19.5 | 49/64 | 20.00 | 25/32 | 25 | 1 | 26.00 | 1-1/32 |

| M22 x 1.5 | 22 | 1.5 | 20.5 | 13/16 | 20.75 | 13/16 | ||||

| M24 x 3 | 24 | 3 | 21 | 53/64 | 21.50 | 27/32 | 27 | 1-5/64 | 28.00 | 1-7/64 |

| M24 x 2 | 24 | 2 | 22 | 7/8 | 22.25 | 7/8 | ||||

| M27 x 3 | 27 | 3 | 24 | 15/16 | 24.50 | 31/32 | 30 | 1-3/16 | 32.00 | 1-1/16 |

| M27 x 2 | 27 | 2 | 25 | 1 | 25.25 | 1 | ||||