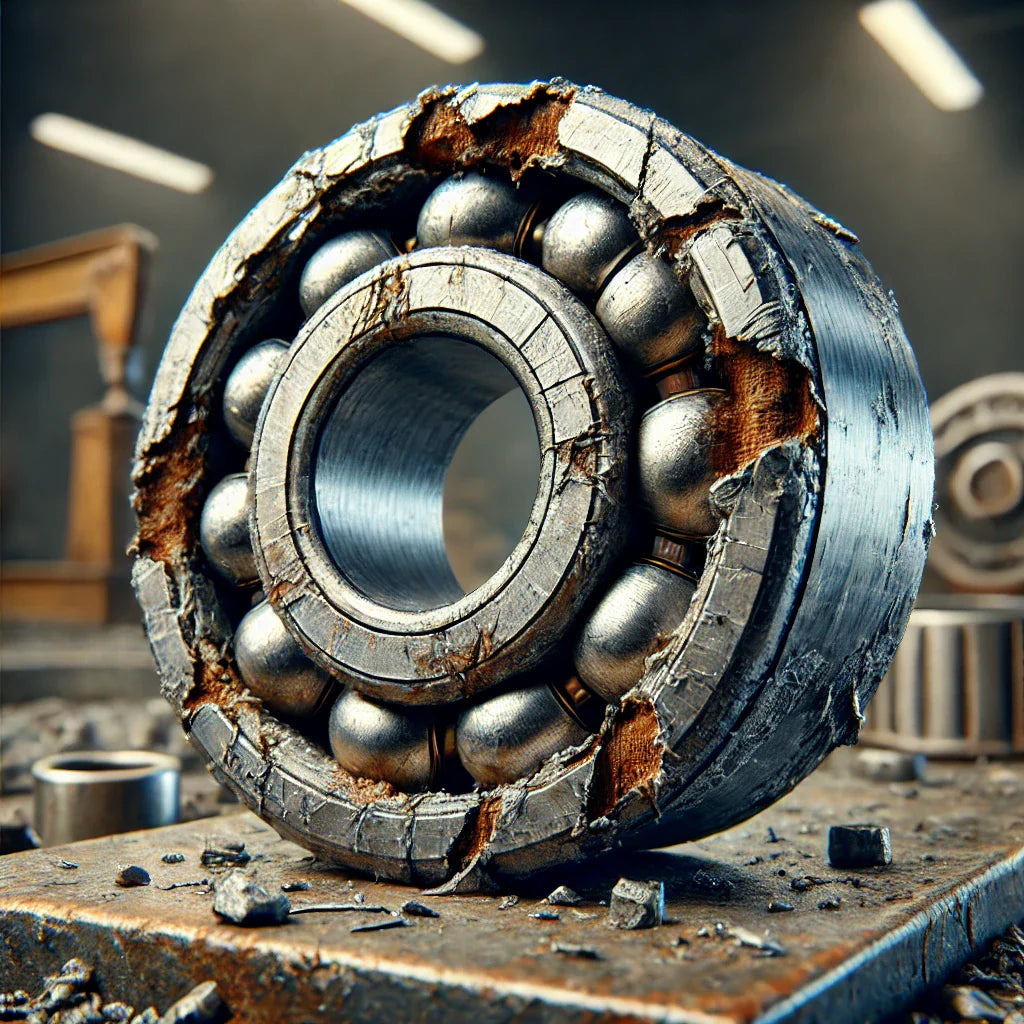

Replacing Damaged Bearings In A machine Is Crucial

Replacing damaged bearings in a machine is crucial for several reasons:

Preventing Further Damage: Damaged bearings can cause excessive vibration, misalignment, and increased friction. If not replaced, these issues can lead to the wear and tear of other components, potentially causing more extensive and costly damage to the machine.

Maintaining Efficiency: Bearings are essential for smooth and efficient operation. When they are damaged, the machine has to work harder, consuming more energy and reducing overall efficiency.

Ensuring Safety: Faulty bearings can lead to mechanical failures, which can be dangerous for operators and anyone nearby. Replacing them reduces the risk of accidents and ensures the machine operates safely.

Reducing Downtime: Operating with damaged bearings increases the likelihood of unexpected breakdowns. Replacing them in a timely manner helps prevent unplanned downtime, keeping the machine running smoothly and minimizing production losses.

Prolonging Machine Life: Regular maintenance, including replacing damaged bearings, helps extend the overall lifespan of the machine. This leads to lower long-term costs by delaying the need for a full replacement.

In summary, replacing damaged bearings is essential for the machine's performance, safety, and longevity.

Preventing Further Damage: Damaged bearings can cause excessive vibration, misalignment, and increased friction. If not replaced, these issues can lead to the wear and tear of other components, potentially causing more extensive and costly damage to the machine.

Maintaining Efficiency: Bearings are essential for smooth and efficient operation. When they are damaged, the machine has to work harder, consuming more energy and reducing overall efficiency.

Ensuring Safety: Faulty bearings can lead to mechanical failures, which can be dangerous for operators and anyone nearby. Replacing them reduces the risk of accidents and ensures the machine operates safely.

Reducing Downtime: Operating with damaged bearings increases the likelihood of unexpected breakdowns. Replacing them in a timely manner helps prevent unplanned downtime, keeping the machine running smoothly and minimizing production losses.

Prolonging Machine Life: Regular maintenance, including replacing damaged bearings, helps extend the overall lifespan of the machine. This leads to lower long-term costs by delaying the need for a full replacement.

In summary, replacing damaged bearings is essential for the machine's performance, safety, and longevity.

Leave a comment