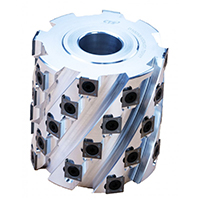

Sheartak Spiral Helical Cutter head for Rockwell Beaver Cat. 48600 6" Jointer with 30 Carbide Knives

Woodworkers are now retrofitting spiral cutterheads to their old planers, and jointers for the following advantages.

* Smoother Finish with no tear-out. Each knife sits at a slight angle and produces a shear-cut. Spiral cutterhead planes board in a staggered way which is much better than a single straight cut. The combined shear and staggered cut eliminates tear-out and leaves a glossy surface finish on even highly figured hardwood.

* Noise is hugely reduced as the spiral cutterhead allows a few knives to cut in a staggered way.

* More than 10 times the life use of high-speed steel. The 15x15x2.5mm inserts are made of sintered tungsten carbide which is much more complicated than high-speed steel. Each insert has four edges.

* Easy to change. The knives are precision ground to a tolerance of +/-0.0004" or +/-0.01mm and are interchangeable. Loosen the screw, rotate 90° for a new edge, and tighten the insert in minutes.

* Dust extraction is easier. The spiral cutterhead produces thinner and shorter chips.

* Low cost to use. Spiral cutterheads produce a smoother finish, reduce or eliminate sanding work, and don't require sharpening, your product will pay for itself in a very short time.

Ask Question About Product

| Technical | |

| Material of Cutterblock | Alloy Steel |

| No. of Spirals | 5 |

| No. of Carbide Inserts | 30 |

| Carbide Insert Size | 15x15x2.5mm R150 30° |

| Screw Size | T25 10#-32TPI |

| Standard Kit | |

| No. of Additional Knives | 5 |

| No. of Additional Screws | 5 |

| No. of Wrenches | 1 |