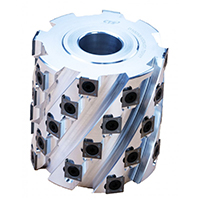

The Beaver JP-3800 jointer-planer was produced by Gallander Foundry & Mag. Co. Ltd. in Guelph, Canada and boasts a sturdy construction that eliminates vibration. Even by modern standards, its sleek design is visually pleasing, and thousands of users still rely on it. We make this spiral cutterhead to upgrade the Beaver JP-3800 jointer planer, allowing loyal customers to take advantage of the benefits of spiral cutting technology, which include:

* Superior finish quality with no tear-out. The inserts on the cutterhead are angled in a staggered manner, allowing for shear-cut effects on even the most highly figured hardwood.

* Reduced noise due to the constant contact of the spiral cutterhead with the board, which only requires a few knives.

* All cutters are made from solid tungsten carbide, which is harder and stays sharp longer than high-speed steel blades. If one edge becomes chipped or dull, simply rotate it 90° for a fresh, sharp edge. Each insert has four cutting edges and can be used four times.

* Easy setup with precision-ground, interchangeable carbide inserts that can be positioned using the taper hole style locking mechanism. Loosen the screws, rotate 90°, and tighten the inserts in minutes.

* Smaller carbide inserts remove shorter and thinner materials, making dust extraction much simpler.

* Spiral cutterheads are more cost-effective in the long run and can pay for themselves quickly.

Spiral Cutterhead Kit includes:

* High tensile strength alloy steel cutter block.

* 30 carbide inserts to be installed.

* 5 extra carbide inserts & 5 extra screws free as spare parts.

* 2 Timken cups pressed inside ready to accept the cones on the pins.

Replace the cutterhead is easy.

The cutterhead removal is as follows:

1. Loosen the two set screws on top of the bearing trunnions (pins) with an Allen key.

2. Loosen the trunnion adjustment screws with a large flat headed screwdriver.

3. Turn machine upside down and remove the front trunnion adjustment pin fully with large flatheaded screwdriver and remove front trunnion.

4. Remove cutterhead and belt.

5. Reverse steps to install new cutterhead.

Ask Question About Product

| Technical | |

| Material of Cutterblock | Alloy Steel |

| No. of Spirals | 5 |

| No. of Carbide Inserts | 30 |

| Carbide Insert Size | 15x15x2.5mm R150 30° |

| Screw Size | T25 10#-32TPI |

| Standard Kit | |

| No. of Additional Knives | 5 |

| No. of Additional Screws | 5 |

| No. of Wrenches | 1 |

| No. of Bearings | 2 |

| Color | |

| Blackoxide | Blackoxide |