Customer Spotlight: Jack’s Magic 16” Jointer Transformation with a Custom Spiral Cutterhead

At Sheartak, we love hearing from customers who push their tools to the limit—and get even more out of them. Today, we’re excited to share Jack’s story and his impressive transformation of a heavy-duty legacy machine: the Gem Magic 16" MF430 Jointer.

Jack's Story

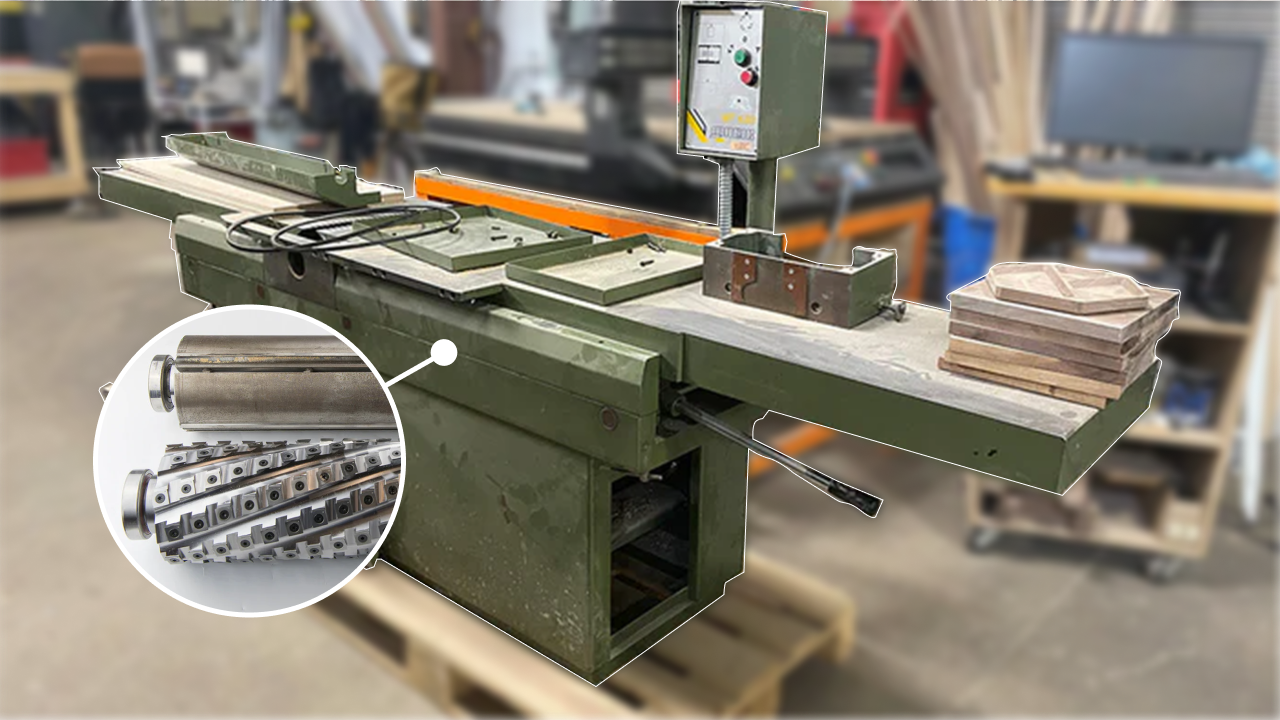

Jack acquired a unique piece of woodworking history—the MF430, a massive 16-inch jointer planer built in 1989 by Magic, a now-defunct Italian manufacturer known for woodworking machinery like table saws, panel saws, and edge banders. Located in Limidi di Soliera in Modena, Italy, Magic produced industrial-grade equipment, and the MF430 is no exception.

This jointer came equipped with a 125 mm diameter, 430 mm long straight knife cutterhead—much larger than the typical 6" or 8" jointers found in most workshops. Unfortunately, after decades of use, the original cutterhead was worn out, and replacement parts weren’t available. Since the manufacturer no longer exists, finding an off-the-shelf upgrade was out of the question.

That’s where Sheartak came in.

We specialize in manufacturing custom spiral cutterheads for legacy and out-of-production machines. For Jack’s MF430, we engineered a precision spiral cutterhead with 180 carbide inserts arranged across 10 rows—built specifically for daily use and premium performance. More details can be found in https://www.sheartak.com/products/magic-mf430-jointer-planer-spiral-cutterhead

Benefits of Spiral Cutterheads

Spiral cutterheads are a game changer for any woodworking operation. Their staggered, angled inserts create a shearing action that delivers smoother, glossier finishes with virtually no tear-out or wash marks. The result? Clean, professional-quality surfaces that don’t even require sanding.

Each carbide insert has four cutting edges. When one edge dulls, simply rotate to the next—no sharpening, no adjustments. This design allows the cutterhead to last 40 to 50 times longer than traditional high-speed steel blades.

There’s another bonus: noise reduction. The staggered insert pattern means only a small section of the cutterhead engages with the wood at any moment, significantly lowering noise levels. That’s good news for your ears—and for your family or neighbors.

Finally, the spiral cutterhead produces finer wood chips that are easier for dust collectors to handle, helping reduce clogs and keeping the workspace cleaner.

Thanks to his custom Sheartak spiral cutterhead, Jack has turned a legacy jointer into a modern, high-performance machine ready for years of daily use.

For those who prefer audio or visual content, here's the YouTube video version: Watch Video.

Leave a comment