Quiz: How Much Do You Know About Spiral Cutterheads?

Spiral cutterheads have transformed woodworking by offering superior cutterhead technology, improved durability, and enhanced precision cutting. Think you know all there is to know about these innovative tools? Test your knowledge with this fun and informative quiz! Answers are provided below.

Here are the questions:

- How Do Spiral Cutterheads Reduce Noise?

- What Is the Most Common Material Used to Make Cutting Inserts?

- Why Do Spiral Cutterheads Save Energy?

- How Long Do Carbide Inserts Last?

- Which of the following factors determines the cutting efficiency of a spiral cutterhead?

- A) The number of inserts on the cutterhead.

- B) The spacing and overlap of the inserts.

- C) The helix angle of the cutterhead.

- D) All of the above.

- Bonus Question: How many renowned jointer and planer brands has Sheartak partnered with and crafted for over the years?

Here are the answers:

1. How Do Spiral Cutterheads Reduce Noise?

Spiral cutterheads feature a staggered arrangement of cutting inserts. This design ensures that only a small portion of the cutter engages the material at a time, reducing noise and vibration significantly compared to straight-knife systems.

2. What Is the Most Common Material Used to Make Cutting Inserts?

Carbide is the most commonly used material for cutting inserts. Known for its exceptional durability, heat resistance, and long-lasting sharpness, carbide significantly outperforms high-speed steel (HSS). Sheartak’s carbide inserts are made from tungsten carbide combined with a binder metal for maximum durability.

3. Why Do Spiral Cutterheads Save Energy?

The staggered insert design reduces the cutterhead’s contact surface, which lowers cutting resistance. This allows the motor to run more efficiently, requiring less power to cut through materials—making spiral cutterheads far more energy-efficient than traditional straight knives.

4. How Long Do Carbide Inserts Last?

Carbide inserts last up to 10 times longer than HSS knives. Their durability and four-sided design allow each insert to be rotated when one edge becomes dull, significantly extending the lifespan of the cutterhead and reducing sharpening costs.

5. Which of the following factors determine the cutting efficiency of a spiral cutterhead?

Answer: D) All of the above.

The efficiency of a spiral cutterhead depends on multiple factors:

- Number of inserts – More inserts distribute the cutting load more evenly.

- Spacing and overlap – Properly arranged inserts ensure smooth and consistent cutting.

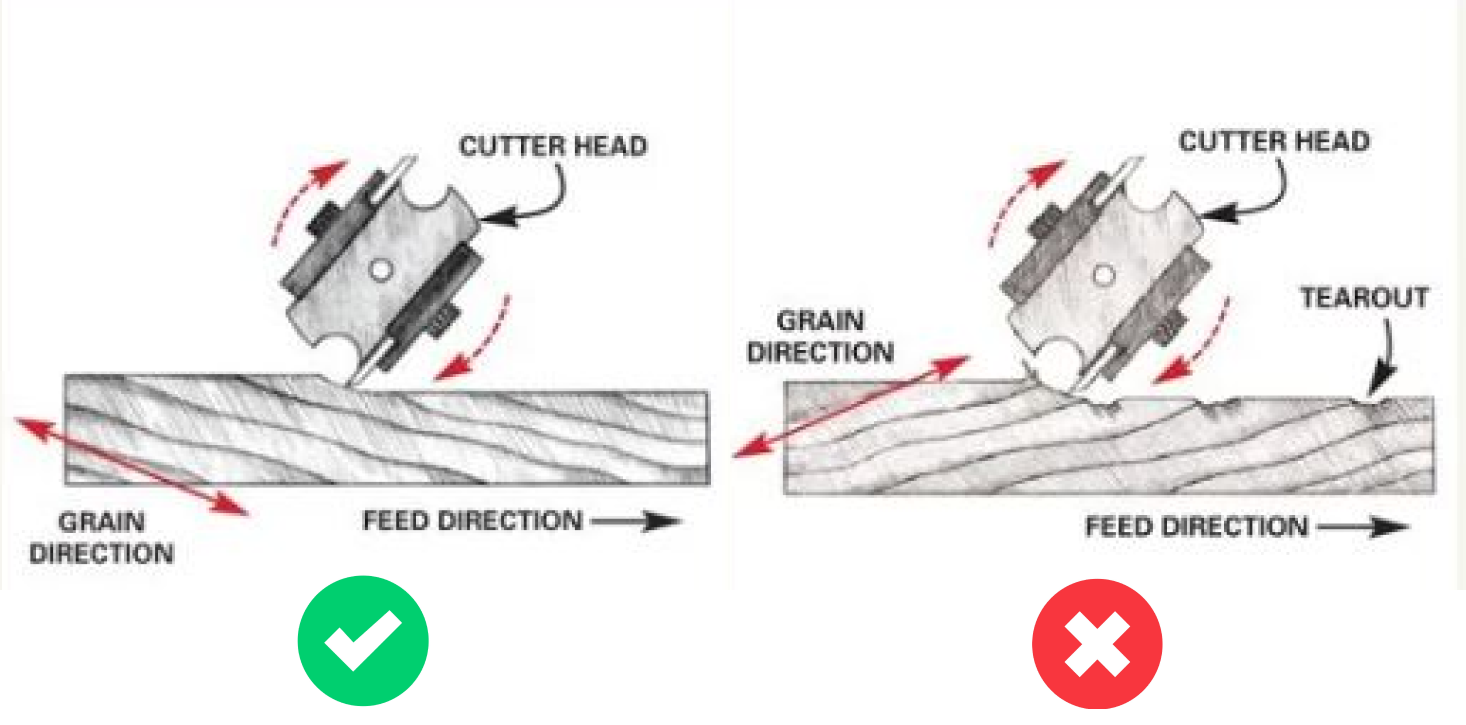

- Helix angle – The angled orientation provides a shearing action, reducing tear-out and enhancing surface finish.

6. Bonus Question: How many renowned jointer and planer brands has Sheartak partnered with and crafted for over the years?

Sheartak has partnered with and manufactured cutterheads for 165 renowned brands, making it a trusted name in precision cutting and cutterhead technology.

Final Thoughts

Spiral cutterheads are a game-changer for woodworking, offering quieter operation, energy efficiency, and superior durability. Sheartak goes even further by providing custom compatibility, ensuring that each precision cutting tool is tailored for maximum performance. Whether you're a professional or a dedicated hobbyist, upgrading to a spiral cutterhead is an investment in precision and long-term value.

Want to test your skills? Take the quiz and see how much you really know about cutterhead technology!

Leave a comment